Manufacturing Process

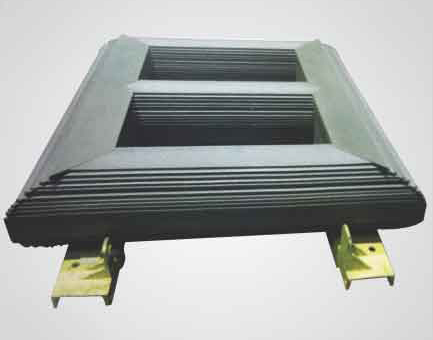

The Magnetic core of the transformers is built up from cold rolled and precisely grained magnetic steel laminations. Hi-B grade & laser scribed laminations are used to decline the load fluctuations and noise levels.

These are leveled at an angle of 45 degrees. The core leg & yoke laminations are deposited in metered joints. The function is primarily used for easy passage of magnetic flux, avoid no load losses, hot spots, and to maintain low noise levels.

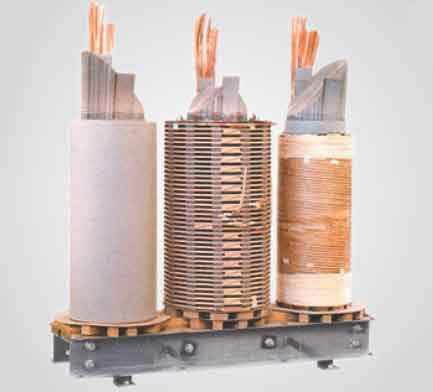

The winding are made out of superior quality electrolytic copper. These are engineered and designed while considering the current and voltage requirements to maximize the utilization of thermal, mechanical & electrical stresses without any fluctuations.

Depending upon the desired design, the required spiral, cross over, helical & disk type windings are utilized.

The active part of transformer is made out of magnetic core with windings & accessories. In order to obtain the desired height & to guarantee total resistance to the short circuit, windings are pressed under the mechanical force with calculated short circuit force.

All connections within windings & bushings and connections between the high voltage tapping & the tap changer are made.

The transformer should be free from any traces of humidity while the vacuum drying process ensures total removal of moisture that exists in the active part. The process is made with effective combination of heating in vacuum cycle.

The oil filtration is one of the major parts and the oil is out sourced from the approved suppliers.

The oil further undergoes for filtration process before filling in to the transformer tank. The moisture is removed by heating under suitable vacuum condition.

The tanks are investigated and cleaned thoroughly and tested to ensure that the active is totally dried and is free from any kind of moisture, before a thick volume of paint is applied. Later, fresh filtered oil is filled in the tank.